Iron offers a distinct advantage over bronze primarily due to cost and mechanical properties, but the benefits vary by application and weapon design. Iron’s affordability and material qualities significantly influenced its adoption over bronze in many contexts, particularly in weaponry and armor.

Iron has two main mechanical advantages. First, its Young’s modulus is about twice that of bronze, making it roughly twice as stiff. Second, iron has a lower density than bronze. This allows iron weapons, for example, blades with the same geometry, to be as stiff as bronze ones but 20-30% lighter. This weight reduction is critical for maneuverability and effectiveness in combat.

Bronze’s ability to be easily cast into complex shapes remains an advantage. It allows production of blades with features such as mid-ribs, which increase stiffness. These ribs are particularly useful on thrusting weapons like spears but reduce cutting efficiency on swords. Therefore, iron’s advantage is most apparent in thin, wide cutting blades where such complex shapes are undesired. This explains the early rise of iron in sword-making, combining lightweight with effective cutting ability.

Regarding hardness and toughness, iron and 10% tin bronze (the typical alloy for European bronze weapons) have similar properties. Both metals can be work-hardened to improve edge hardness. Higher tin content in bronze makes it harder but also more brittle, which limited its use in some regions. Iron with certain impurities, such as nitrogen, competes well with bronze in hardness. However, it is important to note that modern slag-free steel surpasses wrought iron and bronze in tensile strength and hardness.

In armor manufacturing, bronze and iron diverge in their usefulness. Bronze is cold-forged and annealed, making it easier to produce large thin sheets. This property makes bronze preferable for plate armor and helmets during the Bronze and early Iron Ages. Conversely, iron is more ductile and can be drawn into wire, lending itself better to making mail armor (chainmail). The archaeological record supports this, with most ancient plate armor being bronze, while mail armor is typically iron.

Later, as iron industries advanced during the European Middle Ages, mechanization tools like water-powered trip-hammers enabled mass production of iron plate armor. This technological progress reduced costs, diminished bronze’s advantage in plate armor production, and led to iron and then steel plates dominating armor manufacturing.

Bronze also offers superior corrosion resistance. While iron rusts and degrades, bronze develops a stable, protective patina. This durability gave bronze some lasting importance, especially in environments prone to corrosion or where maintenance was difficult.

Even after iron became prevalent, bronze did not vanish. It retained usefulness in specific contexts. For example:

- Bronze continued providing functional weapons comparable to iron in some regions, especially where advanced ironworking was limited.

- Steel, a form of hardened iron, eventually overtook both metals due to its superior hardness and cutting ability.

- Early iron swords benefited from iron’s stiffness and lower cost, causing bronze swords to disappear earlier than iron swords when steel adoption was still developing.

- Medieval armor occasionally incorporated bronze in elements like helmet parts, though iron and steel dominated for cost and performance reasons.

- Bronze was used for maces and similar weapons where casting complex shapes was beneficial.

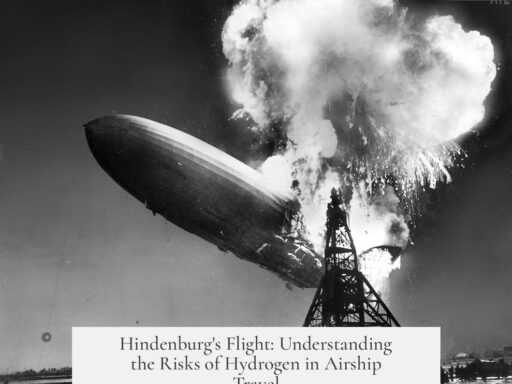

- During the late medieval period, bronze became important in early gun-making. The two main European methods for handguns and cannons were casting in bronze or forging in iron, with bronze’s casting advantage proving crucial.

In summary, iron’s primary advantage over bronze lies in cost and mechanical stiffness, allowing lighter, stiffer cutting weapons. Bronze remained valuable for corrosion resistance, complex casting capabilities, and armor plate production until technological advances favored iron and steel.

| Property | Iron | Bronze (10% Tin) |

|---|---|---|

| Stiffness (Young’s Modulus) | ~2x bronze | Lower |

| Density | Lower than bronze | Higher |

| Hardness & Toughness | Similar when wrought or work-hardened | Similar; can be harder but brittle at high tin |

| Corrosion Resistance | Prone to rust | Patina forms, resists corrosion |

| Manufacturing | Can be drawn into wire; requires forging | Easily cast into complex shapes; better for sheets |

| Use in Armor | Mail armor, later plate armor | Plate armor, helmets |

- Iron is more cost-effective and mechanically advantageous, especially for thin blades.

- Bronze excels in corrosion resistance and casting complex shapes.

- Bronze plate armor was superior early on; iron later prevailed with mechanization.

- Bronze persisted in special weapons and early firearms due to casting ease.

- Steel eventually outclassed both metals, becoming the dominant material.

How Much Really Better Was Iron Than Bronze?

When we ask, how much better was iron than bronze?, the answer is: it depends—on the context, purpose, and era. Iron isn’t simply a straightforward upgrade over bronze. It offers some clear advantages, but bronze holds its own in many ways. Let’s break down this age-old rivalry between the metals and see who really takes the crown.

First, let’s talk money. That’s the main advantage iron had over bronze—cost. Iron is more abundant in the earth’s crust than the tin and copper alloy that forms bronze. This means iron was generally cheaper to produce and more accessible to cultures transitioning from the Bronze Age. In ancient times, cost mattered as much as quality, because armies and smiths needed material in bulk.

Iron’s Mechanical Edge

Iron boasts two key mechanical advantages: it’s about twice as stiff as bronze, and it’s also lighter. In technical terms, iron’s Young’s modulus is roughly double that of bronze, meaning it resists bending better. Plus, its lower density means you can get comparable stiffness in a blade that weighs 20-30% less. More bang for fewer pounds!

But hold on, bronze has one trick up its sleeve here—casting. Bronze can be melted and poured into complex shapes easily, allowing smiths to create blades with mid-ribs or intricate designs to increase stiffness without adding weight. Those mid-ribs work well on spears and thrusting weapons, but ironically, they’re a drag on sword-cutting performance.

So where does iron shine brightest? On thin, wide cutting blades like swords. Thanks to its stiffness and lighter weight, iron makes cutting weapons that balance sharpness and durability, without the shaping restrictions bronze faces. This practical advantage probably explains why we see iron sword blades catch on first in the archaeological record.

The Hardness and Toughness Debate

Surprisingly, when it comes to hardness and toughness, iron and typical 10% tin bronze are quite similar. Both can be “work-hardened,” a process that makes edges tougher by deforming and strengthening the metal surface. However, iron with some impurities (think nitrogen) can rival bronze’s hardness. Meanwhile, some higher-tin bronze alloys get harder but risk brittleness— a dangerous trade-off in battle.

It’s worth noting that modern steel (which is highly refined iron) blows both bronze and wrought iron out of the water in hardness and strength. But in ancient and early medieval times, the iron available was closer in performance to bronze than you’d expect.

Armor: Who Wins the Protective Battle?

For armor, bronze flexes its muscles. Because it’s cold-forged and annealed occasionally, making large, thin bronze sheets is easier than iron sheets. This made bronze the go-to metal for plate armor and helmets in early history. On the flip side, iron is far more ductile and can be drawn into wire easily—perfect for manufacturing chainmail. So, history shows us mostly bronze plate armor and iron mail armor.

Eventually, as iron-working improved and water-powered hammers evolved, making large iron plates became cheaper and more practical. This shifted the tide back to iron for plate armor in the later medieval period. The industrial edge lets iron catch up, showing how technology and economy influence material dominance.

Corrosion: Bronze’s Hidden Superpower

Iron rusts, plain and simple. Bronze develops a stable patina, which protects it from deeper corrosion. This means bronze artifacts often withstand the test of time better—especially outside controlled environments. For warriors and smiths, however, regular maintenance was the norm. Still, bronze’s corrosion resistance is a meaningful advantage in damp climates and for long-term equipment storage.

The Later Tale of Bronze and Iron

By the medieval period, bronze was still around, but mostly in specialized roles. Some parts of helmets mixed bronze and iron for cost or casting reasons. Bronze found new life in weapons like maces, benefiting from easier casting of complex shapes. And then came the gunpowder era, where bronze’s casting ability made it essential in making cannons and early handguns. Forged iron and bronze coexisted as winners in different fields.

Iron, and especially steel, took over swords wholesale. Why? Because the higher stiffness of iron allowed for lighter, better cutting blades. Plus, iron’s lower cost stamped out most of bronze’s sword market. Steel later upped the ante with superior hardness, but iron was the stepping stone that made sweeping changes possible.

So, How Much Better Was Iron Than Bronze?

Iron was notably better in cost, blade weight, and stiffness—meaning lighter, sharper swords for less money. Bronze’s casting advantages and corrosion resistance let it remain relevant, especially in armor and weapons needing complex shapes or thin plates. Both metals had sweet spots.

Ask yourself: Would you want a lighter sword that slices better, or a corrosion-resistant shield? The ancients didn’t just pick one—sometimes they mixed and matched, combining strengths of both metals depending on need and resources.

In summary, iron offered a significant step up in economics and specific weapon forms, but bronze kept its niche—dominating plates, complex shapes, and corrosion resistance. The transition wasn’t an overnight revolution; it was a nuanced evolution shaped by technology, costs, and battlefield needs.

And for those who dream about ancient smithing, remember: the iron age didn’t so much dethrone bronze as it redefined the rules of the game. Now, what metal would you choose for your next adventure?