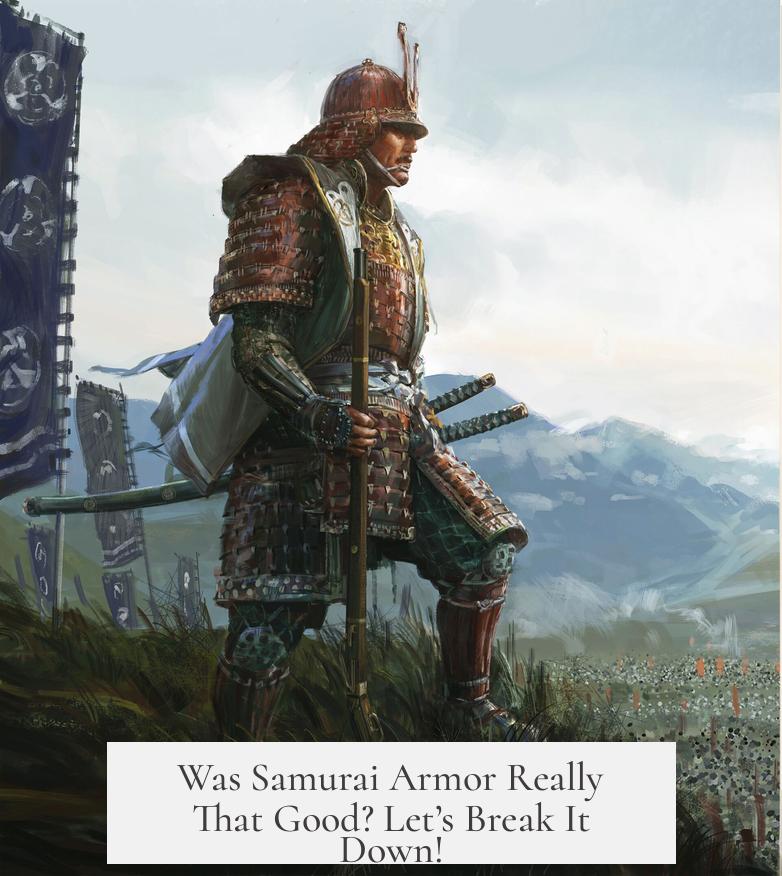

The samurai armor was good due to its advanced materials, forging techniques, and functional design that balanced protection with flexibility. It combined steel and iron to resist penetration and absorb impact, showing sophisticated metallurgical skill that rivaled contemporary armors worldwide.

Samurai armor consisted mainly of hardened rawhide (nerigawa), iron, steel, or a combination of metal materials. Contrary to popular belief, Japanese armor was not primarily lightweight non-metallic material but included substantial metalwork. This composition is confirmed by historical artifacts and sources.

During the Azuchi Momoyama period (1568-1603), samurai armor evolved to become lighter on average compared to European armor. However, there was significant variation. Armor types ranged from lamellar and chainmail to robust plate armor, meaning samurai could wear highly protective gear as needed.

The period relevant to the samurai’s classic armor style is the late Muromachi to Azuchi Momoyama era (1532-1614). This timeframe aligns with the production of armors comparable to medieval European ones, emphasizing a peak in Japanese armor technology and design.

| Aspect | Details |

|---|---|

| Materials | Steel outer layer and thicker iron inner layer |

| Forging Technique | Jumonji-Kitae (cross or two-ply forging) |

| Construction Purpose | Steel resists arrows/bullets; iron absorbs impact shock |

| Performance | Prevents shattering or denting of armor plates |

| Historical Evidence | Armor items from late 16th to early 17th century show this technique |

The Jumonji-Kitae forging method involved repeatedly heating and hammering iron to develop specific grain patterns. Steel and iron were welded with grooved chequerwise surfaces to allow charcoal to escape during forging. This process ensured a strong, layered plate.

The bi-metallic construction offered a functional advantage. Steel acted as a hard surface against penetration by arrows or bullets. The thicker iron layer underneath absorbed the shock. This mutual interaction avoided the failure seen in single-metal plates, such as cracking or piercing.

Such innovative armor design demonstrates that samurai armor was not merely ceremonial or symbolic. It embodied practical defense needs against contemporary weapons and maintained mobility for warriors on the battlefield.

- Samurai armor used metal plates of steel and iron, not lightweight solely rawhide.

- Forging techniques created strong, dual-layer armor resisting penetration and impact.

- Armor styles varied widely, offering both protection and lighter options.

- Historical examples confirm this sophisticated metallurgical approach.

Was Samurai Armor Really That Good? Let’s Break It Down!

Quick answer: Yes, samurai armor was impressively good — and not just because it looked cool in movies! The craftsmanship, materials, and design were highly advanced for their time, adapting cleverly to threats like arrows and even bullets. However, many myths about its lightness and fragility don’t hold up when scrutinized.

So, how good was samurai armor really? Let’s explore the truths and bust the myths, piece by piece.

The Material Reality: Not Just Lightweight Plastic!

Contrary to what pop culture often suggests, samurai armor was not made of flimsy or non-metallic materials. It used hardened rawhide known as nerigawa (練革), iron, steel, or a mixture of these. So if you imagined samurai fighting with cardboard boxes strapped on, think again!

This blend was no accident. Each material had a specific role, working in harmony to provide protection while balancing weight. This careful selection makes samurai armor both durable and effective—no downside there.

A Diverse Arsenal: More Than Just “Light Armor”

Looking closer at the different styles, samurai armor varied widely. The Azuchi Momoyama period (1568-1603) gave rise to armor notably lighter on average than European knights’ plate armor of the same era. However, this doesn’t mean it was weak.

Variations included lamellar (or small linked plates), chain mail, and several types of plate armor. Some versions were even quite robust, showing that “light” doesn’t automatically mean “fragile.”

This diversity ensured samurai warriors could adapt armor to suit their specific roles or battle needs. Ever think about how we choose gear today based on mission types? Samurai were doing this centuries ago.

When and Where? The Perfect Timing of Samurai Armor’s Peak

According to Edo period scholar Sakakibara Kozan, the “medieval” equivalent for Japanese armor aligns with the late Muromachi and Azuchi Momoyama periods (1532–1614). This frames when samurai armor was competing head-to-head (literally!) with European armor types.

This timeline matters: it helps us compare apples to apples rather than misunderstand the role and technology of samurai armor by mixing eras.

Forging Secrets: The Jumonji-Kitae Technique

Samurai armor wasn’t just hammered together by brute force. The plates were forged using an intricate method called Jumonji-Kitae (十文字鍛え). This involved careful heating and hammering to create a special grain pattern, which enhanced strength and durability.

The plates were bi-metallic—steel on the outside and iron on the inside, with the iron layer being twice as thick. The welding surfaces were grooved checkerwise (think: small channels) to let charcoal and gases escape during forging.

Sound technical? It was. This sophisticated approach gave samurai armor a dual-edge advantage.

Why Two Metals? The Science of Bullet and Arrow Defense

“An all-steel plate would shatter under a heavy blow, and an all-iron one would dent or pierce — mixing the two creates a plate that resists both.”

This principle was exactly why samurai armor worked so well. Steel resists penetration, stopping arrows and bullets cold. Iron absorbs and deadens the shock, preventing the entire plate from breaking under impact.

This smart design optimized both protection against piercing and blunt force, making the armor formidable on the battlefield.

Proof? Historical Artifacts Speak Volumes

Armor from the late 16th and early 17th centuries still exists today, showcasing this bi-metallic structure. These aren’t just museum props; they are solid evidence of ancient Japanese metallurgical genius.

Any samurai armor you see in museums or collections? Likely, it’s a tangible piece of this sophisticated tradition—more than just ornamental.

So Was Samurai Armor Good?

To wrap it up: absolutely. It was a finely crafted protective gear built with advanced forging techniques, making it effective against both projectiles and blunt force.

While lighter than European suits of armor on average, it was no fragile costume. Samurai armor adapted in style and thickness, from lamellar mail to strong plates, to meet different demands.

If you’re looking for a takeaway, think of samurai armor as a smart blend of technology and practicality. It balanced protection and mobility better than many of its European counterparts. So next time someone jokes about “samurai armor being just leather and luck,” you’ll know better.

Quick Tips for Armor Enthusiasts

- Want to spot a samurai armor myth? Look for claims of “purely light, non-metallic” construction. They’re fiction.

- Check the armor’s forging method if you visit a museum—bi-metallic plates signal authentic craftsmanship.

- Remember period context: armor evolves over time. Azuchi Momoyama period armor had distinct advantages in weight and design.

Final Thought: What Can We Learn Today?

Samurai armor teaches us balance. The balance of materials—steel for strength and iron for shock absorption—is a metaphor for good design that stands the test of time. Even centuries ago, armor makers understood how to make gear that does one job without sacrificing the other.

So the next time you read about samurai armor, give it the respect it deserves. It wasn’t just good; for its era, it was brilliant.